Manufacturing a finished product from raw materials with the application of various components, involves implementation of a sound planning and strategy through a proper management system.

Since every business has its own certain requirements and liabilities to run successfully without causing any future damage. An integrated ERP software & manufacturing system fits into that space as it can smartly manage all the business process connected to manufacturing of any product.

An ERP Manufacturing Software is that software system which provide a platform for assessing, managing and accounting all the informations about different manufacturing resources and obtaining the finished product which can make the system more reliable and effective.

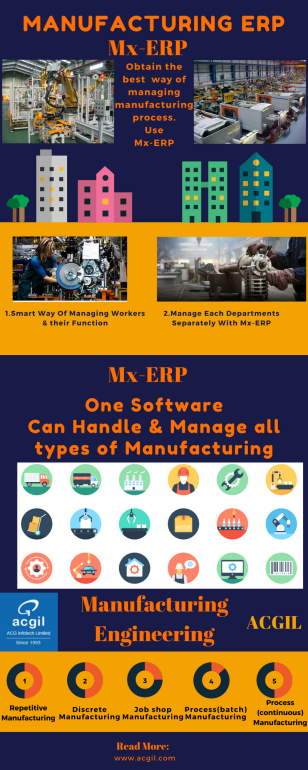

Now there are various ERP for manufacturing industry and to decide which one will suits to your business needs some market research. However, out various ERPs available you will find that Mx-ERP offered by ACG Infotech Limited, India is the best suitable manufacturing ERP software for your business in India. It is affordable, reliable and can be customized to suit your business needs and requirements.

Mx-ERP is smartly designed as it can be used for wide range of manufacturing industries making it most effective ERP for manufacturing industry.Mx-ERP is completely a premier ERP software for manufacturing that can automate financial, inventory, production, sales/quoting & others.

Some Major Benefits of Mx-ERP

1.Improved Visibility: It ensures all departments can access and view the same consistent & accurate data in real time.It makes smoother coordination & better execution of all related processes and procedure.

2.Increased Efficiency: It allow firms to track all supply chain activities in great details from start to finish there by improving efficiency by eliminating any hindrance.

3.On-Time Delivery: It provide all the essential informations that can ensure on-time delivery of any service or product purchased.

4.Enhanced Product Quality: It make easier for business firms to monitor product defects & problems pinpoint exactly where is issue whether in designing or product processing. It suggest what steps need to be take to ensure products of utmost quality.

5.Reduced Costs: It reduces the costs in many ways as better tracking of components & turnover of finished goods combined with more accurate demand planning, eliminate excess inventory cost & others,

6.Improved Collaboration: It enable companies to share important production related information with external constituent as well such as vendors, supplier & distributer. This improves communication & enables better coordination of activities among these key business partners.

7.Tracks Changes In Demands: Capitalize your customers buying habit and purchase trends. It increase up shells by recommending products to customers. ERP allows you to monitor what you doesn’t sell.

8.Consolidate Inventory: Maximize cash flow by stocking the minimum amount of inventory to satisfy the maximum number of customers.It enables to control inventory costs, trend analysis and changes in demands, avoid stock-outs and to decrease excess inventory.

9.Immediate access to key data: It integrates different departments into one software system. Taking customers order and fulfilling them get quick. This database demonstrate real time,accurate data allowing for making quick decisions.

10.Easy Accounting: With all the financial into one database, accounting of all expenses and profits can be easily done.